Miniature Parts

ISO 9002 CERTIFIED

FIXTURE SETUP for cutting six parts at once using

.002 wire.

|

.002 Diameter Wire — Internal Gear

.002 Diameter Wire — Internal Gear

ISO 9002 CERTIFIED

- Required Tolerance ± .0001

- Use Ø.002 Wire.

- Cutting accuracy is most important.

|

|

18" Tall Aluminum Work Piece

ISO 9002 CERTIFIED

- 18 inch tall aluminum work — submerged.

- Required straightness .001" over 18"

height.

|

|

Titanium Needles

Titanium Needles

ISO 9002 CERTIFIED

- Parts MUST be burr free!

- Parts must have no blue or yellow discoloration!

- Parts MUST maintain a 7 Ra or better surface finish.

|

|

Example of Stacking Work Pieces

ISO 9002 CERTIFIED

- Design fixture to stack 6 parts to optimize cycle

time.

- Tolerance ± .0010

|

|

Power Generation Turbine Blades

ISO 9002 CERTIFIED

- Cut Fast! using brass wire.

- Stainless steel — soft.

- Straightness to be held to ± 0.001 inch.

- No Wire Brakes.

|

|

Engine Turbine Blades

ISO 9002 CERTIFIED

- Cut four fixturing notches in the casting.

- No Wire Breaks.

- Tolerance ± 0.0006 shape accuracy.

|

|

Punch and Die

ISO 9002 CERTIFIED

- Tolerance ± .0002

- Use Ø .010 wire.

|

|

Precision Die Matching

ISO 9002 CERTIFIED

- Tolerance ±. 0001

- Use Ø.010 wire.

- Material 2.5 inches thick.

|

|

7min(Ra) surface finish without isolated tooling

|

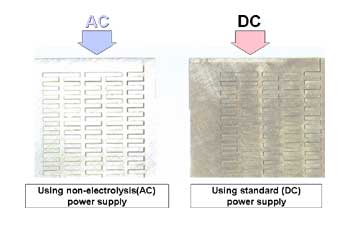

Less work-piece oxidation

|

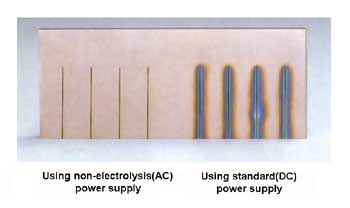

Reduced discoloration in titanium

|